USA Tungsten Projects

In December 2025, Viking Mines announced it had entered into a binding Terms Sheet with USA based

BLK Group LLC (“BLK Group”), to acquire six tungsten projects located in the Tier 1 jurisdiction of Nevada, USA (“USA Projects”).

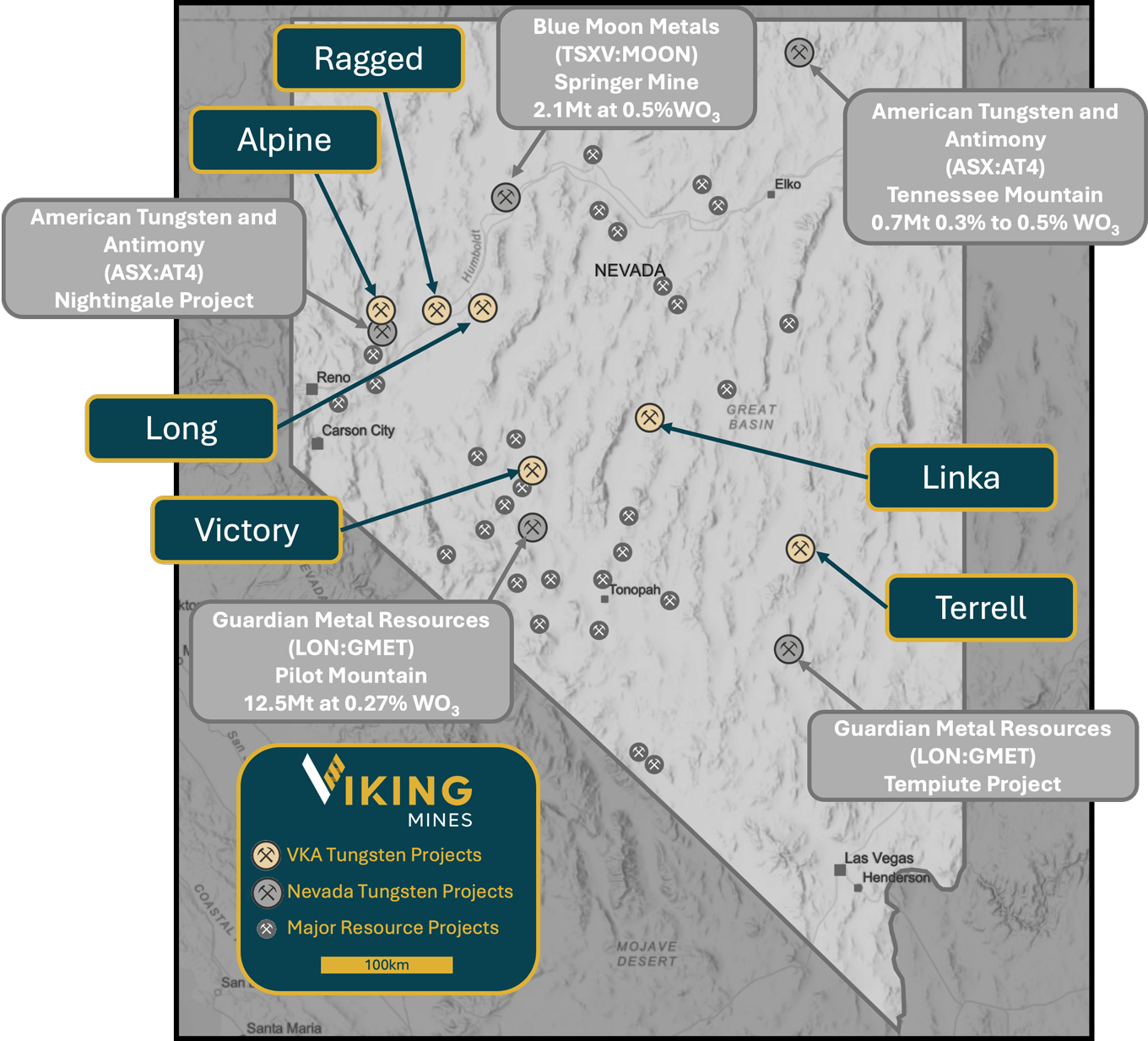

The six projects to be acquired by Viking are Linka, Alpine, Long, Terrell, Ragged and Victory, all located within the state of Nevada, USA (Figure 1). Four of the projects have had ore mined via both open pit and underground operations throughout the 20th century for a total production of ~123,000t at 0.54% tungsten oxide (“WO3”).

The flagship Linka Project reports significant historical assays including underground channel sampling of 6.1m at 1.50% WO3 and drillhole results including 10.1m at 0.79% WO3 (DDH-8) from 39.6m, both demonstrating the exceptional high-grade intercepts which can be attained from the project. Mineralisation has been extracted from three historical mines occurring over ~820m strike length with significant opportunity to identify and define resources across the project.

The transaction has received significant endorsement with a $750,000 investment from American Tungsten Corp (CSE:TUNG, OTCQB:TUNGF, FRA:RK90) who will become a substantial shareholder of Viking via a strategic placement into the Company.

Strategic Development Plan and Next Steps

Viking has developed a three-pillar strategy to advance the portfolio: aggressive exploration to define a mineral resource, metallurgical testwork to refine downstream processing, and active engagement with the US Government to secure funding for this critical mineral. The primary focus will be the flagship Linka Project due to its scale and production history, while parallel field investigations advance the broader pipeline to provide optionality.

The Company has commenced due diligence, including a site visit to Nevada. Immediate work programmes over the coming weeks include:

- Data Compilation & Verification: Aggregation of historical datasets into a digital database alongside legal claim verification and on-ground assessment.

- Sampling Program: Execution of initial rock chip sampling to verify historical grades and collection of metallurgical (>200kg) composite samples for metallurgical testwork and mineralogical composition.

- Target Generation: Engagement of geological and geophysical consultants and contractors to undertake fieldwork (mapping and geophysical data collection) to support the development of JORC (2012) exploration targets for each project.

- Permitting: Commencement of drill permitting with the US Federal Agencies to facilitate the upcoming drill phase.

Linka Project

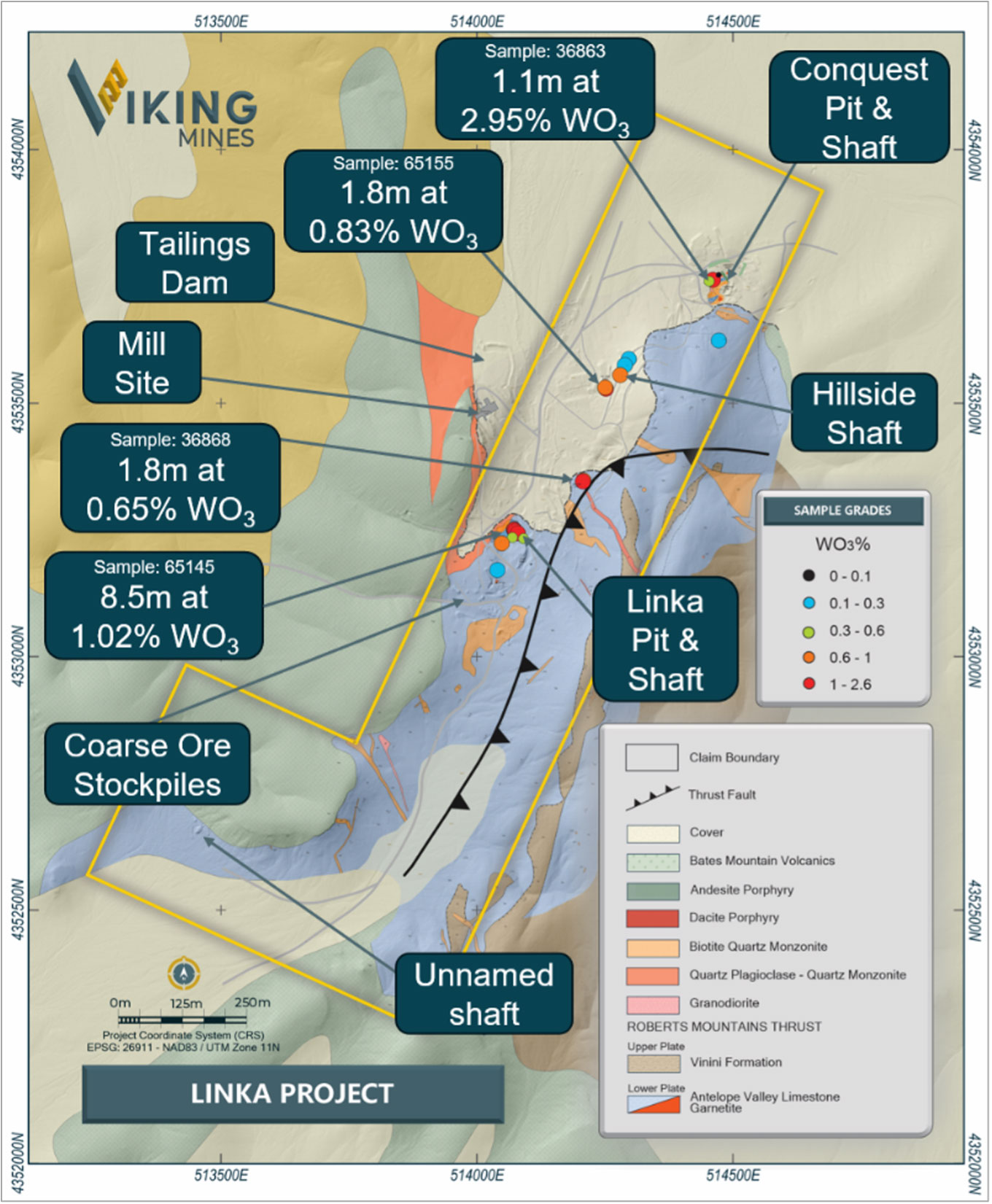

The most significant of the projects is Linka and encompasses the 3 historic mines of Linka, Hillside and Conquest

(Figure 2) with recorded production of ~65kt at 0.49%WO3 mined.

Tungsten mineralisation occurs as a skarn (tactite) along a contact zone between intrusive granodiorite and carbonates (limestone). Tungsten mineralisation occurs as scheelite (Figure 4) and is exposed intermittently for ~820m strike length along the northeasterly trending contact zone (Figure 2). Extensions to the NE and SW remain open and are covered by alluvium and tertiary age tuffs.

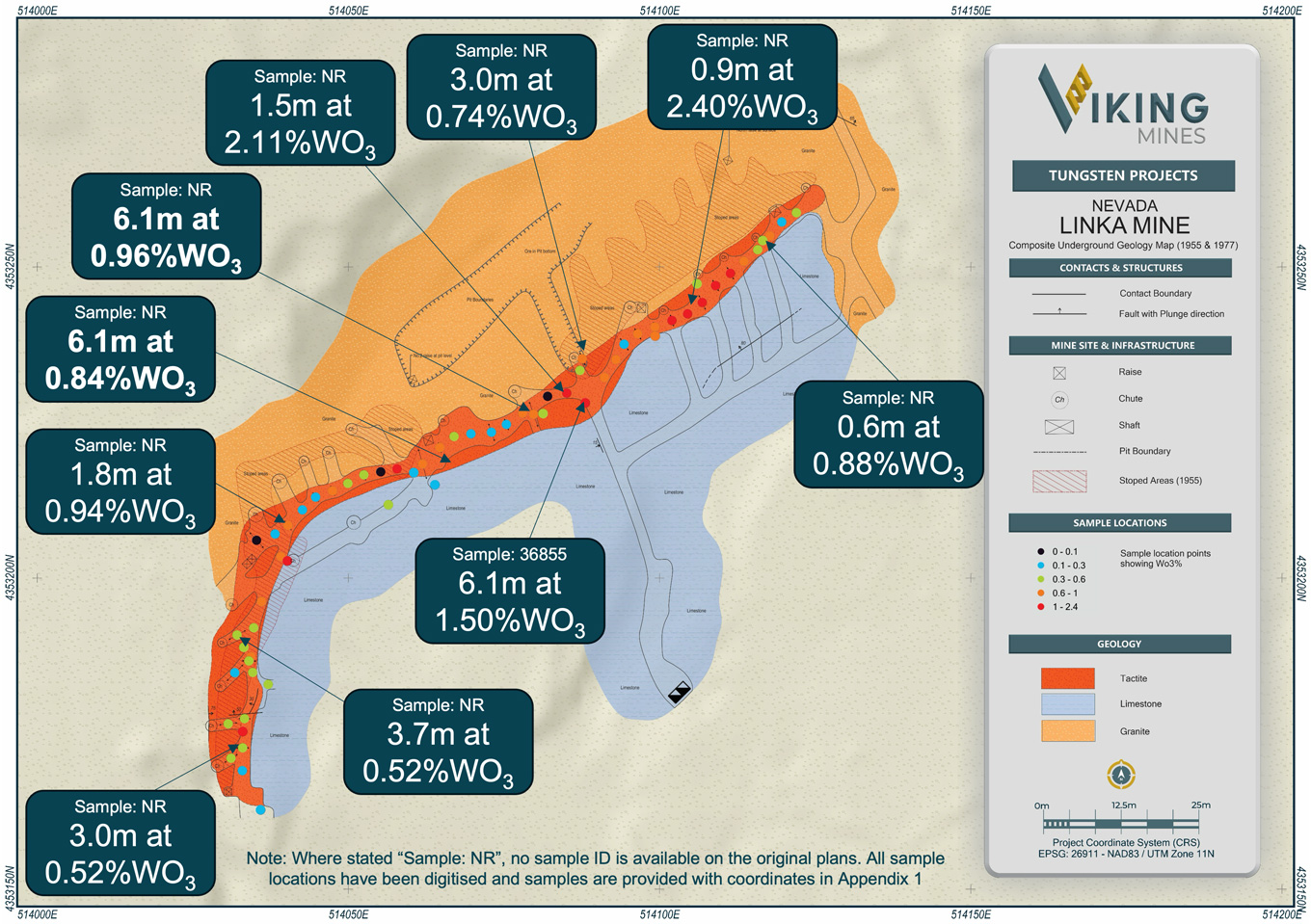

Linka Mine

Underground mapping completed in the 1955 and 1977 confirms the Linka historical orebody as 470ft (~143m) long with an average width of 40ft (~12.1m) (Figure 3). Mineralisation remains open to depth and Viking is trying to obtain historical drilling records from exploration drilling completed in the late 1970’s.

Exceptionally high tungsten grades over significant widths up to 6.1m occur within the Linka underground on the 150ft level (Figure 3), including;

- 6.1m at 1.5% WO3

- 6.1m at 0.96% WO3

- 6.1m at 0.84% WO3

- 1.5m at 2.11%WO3

Historical assay intervals and drillhole IDs for 10 holes drilled in c.1953-54 have been identified. The Company is attempting to source collar locations, azimuth and dip of the drilling as part of the due diligence process underway and at this time cannot spatially locate the drillholes. However, documents indicate all drilling is from the Linka historical orebody.

Stand out intercepts from this drilling include;

- DDH-8; 10.1m at 0.79% WO3 from 39.6m

- DDH-18; 8.5m at 0.56% WO3 from 50.9m

- DDH-6; 3.8m at 1.01% WO3 from 31.4m

Cautionary Statement: Visual estimates of mineral abundance should never be considered a proxy or substitute for laboratory analyses where concentrations or grades are the factor of principal economic interest. Visual estimates also potentially provide no information regarding impurities or deleterious physical properties relevant to valuations.

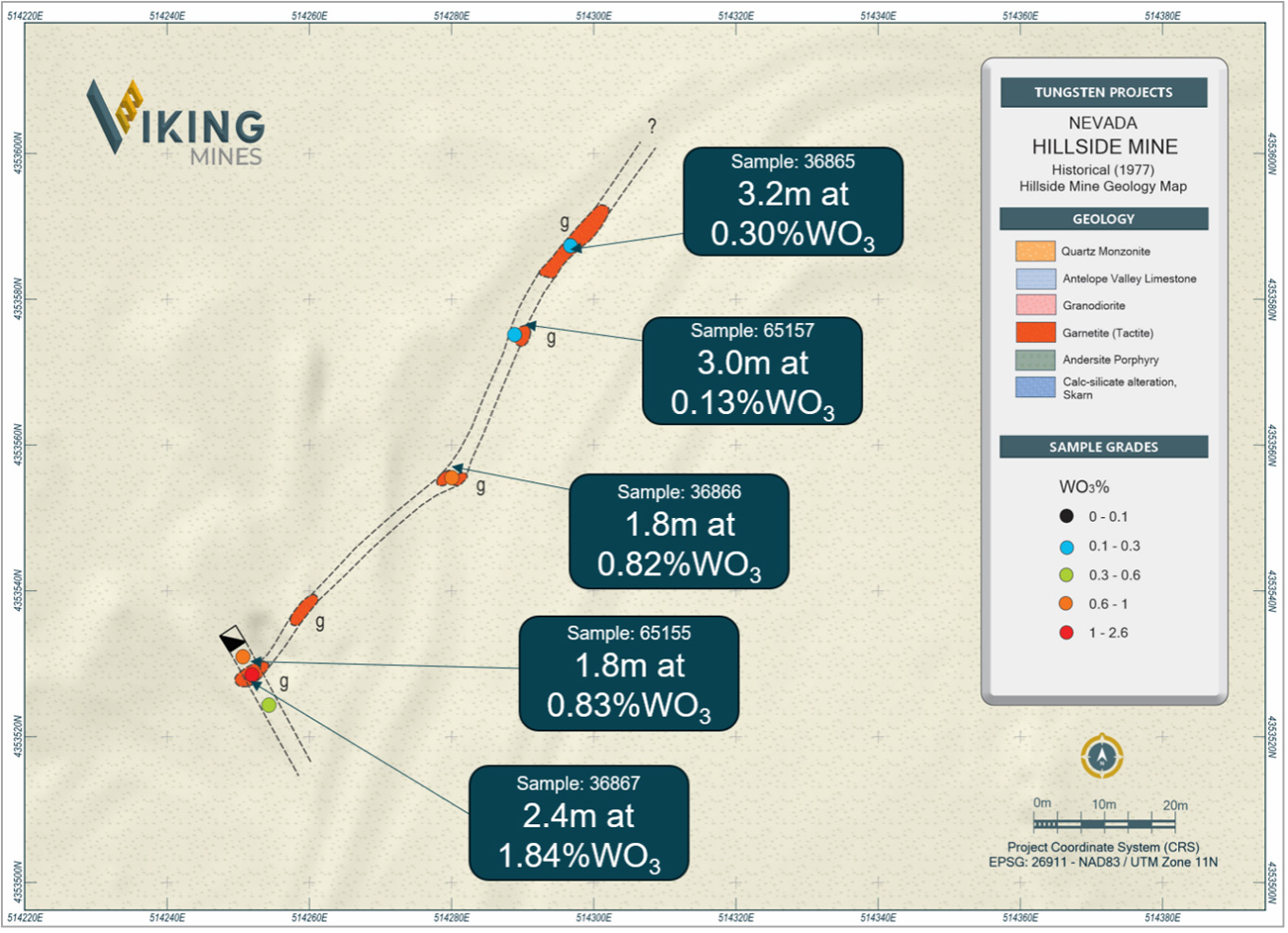

Linka – Hillside Mine

The Linka-Hillside Mine is located ~330m to the NE of Linka and was developed via a 100ft inclined shaft. Historical mapping and sampling (Figure 5) from the 1970’s has returned high-grade results including;

- 2.4m at 1.84% WO3

- 1.8m at 0.82% WO3

Significantly, a surface sample located halfway between Linka and Hillside has returned 1.8m at 0.65% WO3 (Figure 2), indicating potential for additional mineralisation to be discovered along the mineralised trend.

As part of the ongoing due diligence, samples have been collected from Hillside. During the sampling process, a shortwave UV lamp is used to identify scheelite based on its fluorescent properties. Figure 1 shows samples from Hillside under UV light and the abundance of scheelite observed (visual estimate of 1.0-2.5% scheelite).

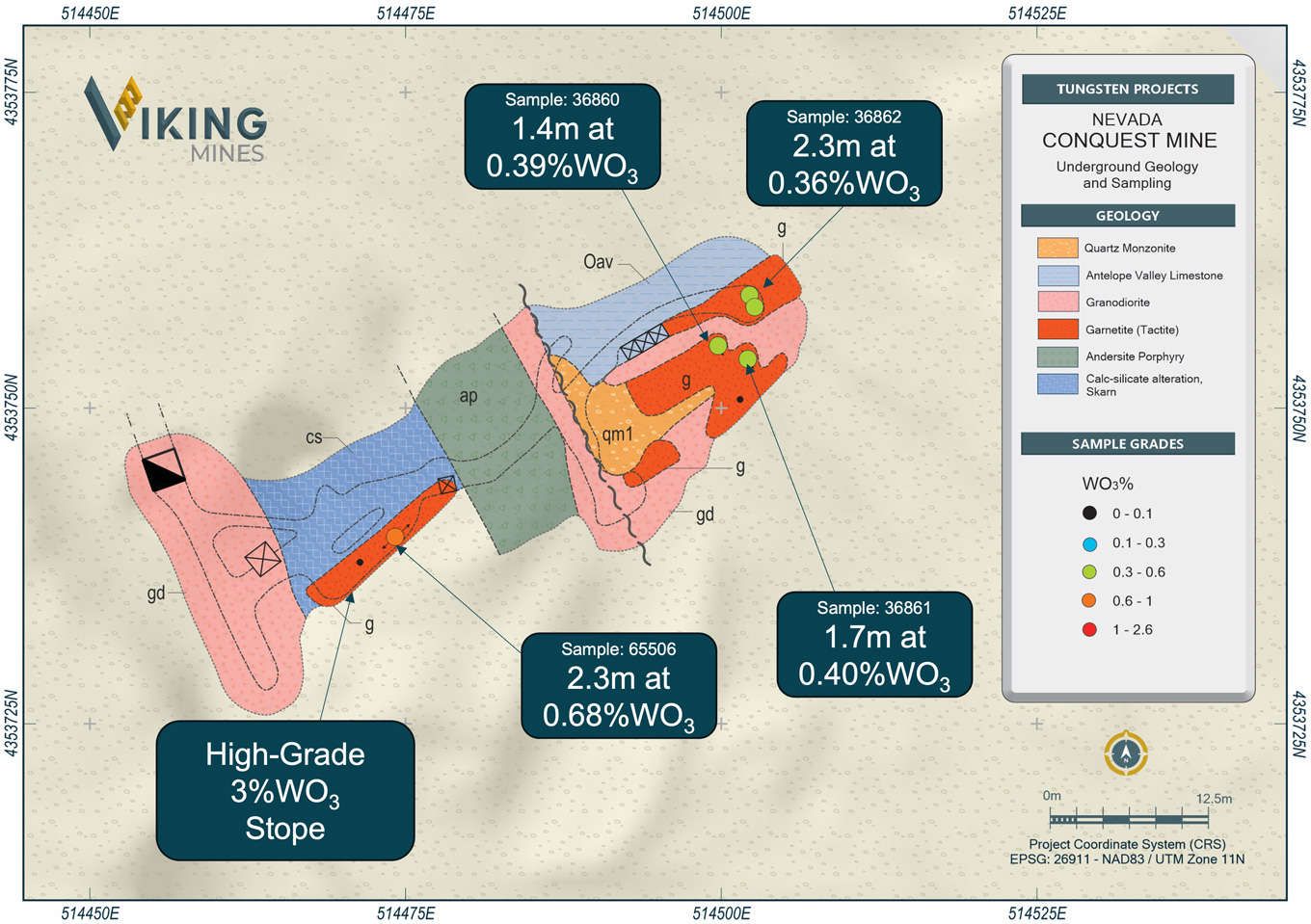

Linka – Conquest Mine

The Linka-Conquest underground mine is located 660m NE of Linka (300m NE from Linka-Hillside) and was developed via a 100ft vertical shaft with underground workings on the 50ft and 100ft levels. Mineralisation is open to the NE and SW.

Mapping and sampling from the 1970’s indicate very high grade stopes were mined, up to 3.0% WO3 (Figure 6). In addition, exceptionally high-grade samples have been recorded in both surface and underground sampling.

- 1.1m at 2.95% WO3

- 0.7m at 2.28% WO3

- 2.3m at 0.68% WO3

Linka Project Historical Production

Mining occurred at the Project between 1941 and 1956. A 360 tonne per day flotation plant was constructed in 1955 and records indicate that approximately 65kt of ore at 0.49% WO3 was processed. In 1956 the US government suspended its tungsten buying program and operations ceased.

The majority of ore was mined from the Linka Mine with a 5m x 4m vertical shaft developed to a depth of 300ft (~91m). Underground development was established on the 150ft level (~45.5m) with ore mined from shrinkage stopes feeding the mill (location shown on Figure 3). No development was undertaken on the 300ft level due to the mine ceasing operation. Records indicate that the historical orebody continues to depth below the 150ft level.

At Linka-Conquest, bulldozer clearing exposed ore averaging 3% WO3. A 25ft pit was subsequently mined and vertical shaft to 130ft (~40m) which produced ~354 tonnes at 2.71% WO3. Subsequent shipments reported to exceed 1% with a total tonnage mined estimated at 4,700t at 1.00% WO3.

At the 100ft level, a zone has been exposed which is 40ft (~12.2m) long and 12ft to 20ft (3.7m to 6.1m) wide and open to the northeast.

A coarse ore stockpile has potentially been identified during the due diligence site visit which encompasses large (oversize) mineralised rocks which may have been too large to be processed by the mill (Figure 7). The Company has collected a ~>70kg composite sample for grade analysis and metallurgical testwork and will undertake a sampling programme and survey of the material as a potential future early source of mineralisation for further testwork.

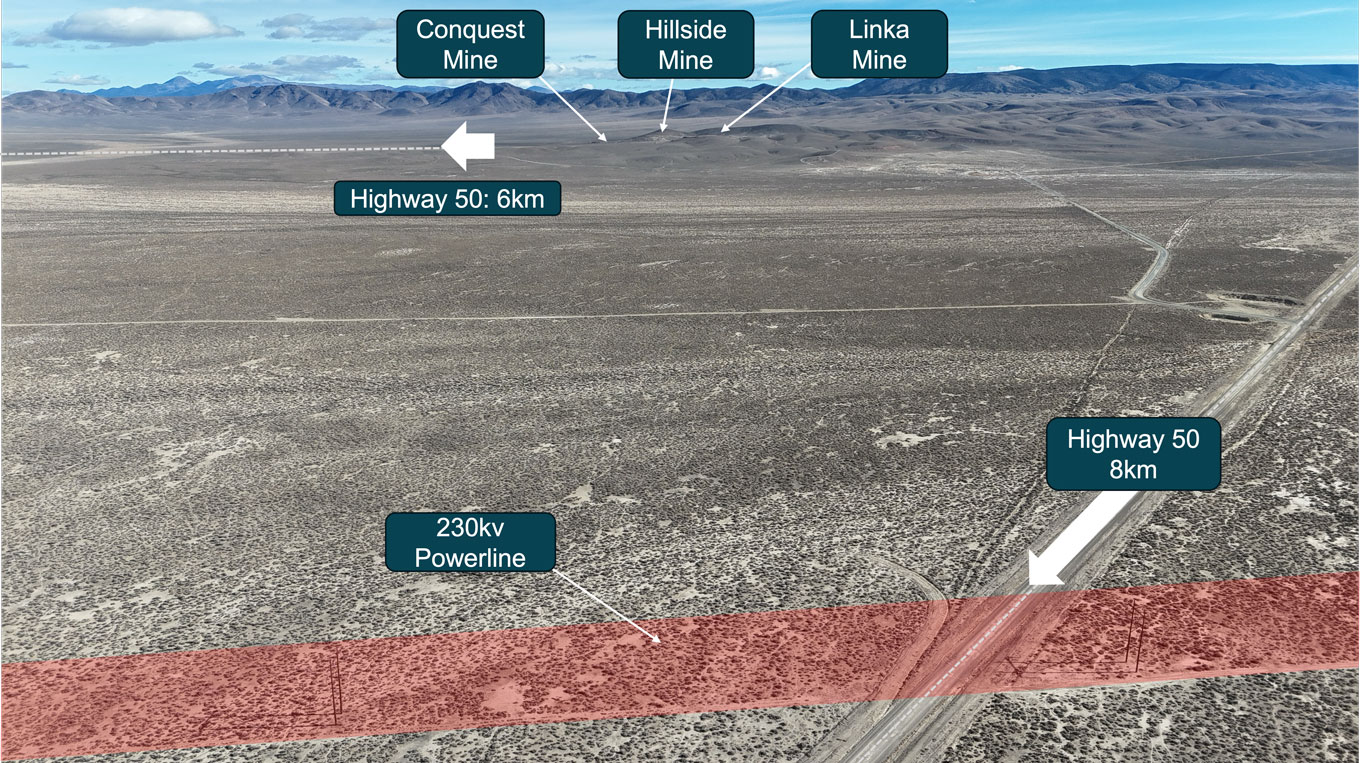

Infrastructure Considerations

The Linka Project is well serviced by critical infrastructure (Figure 8). Key aspects are;

- 230 kv powerline runs 4.5km west of the Linka Open Pit providing a potential future source of grid power.

- The project is well-serviced by existing infrastructure, located just 7km south of Highway 50 with excellent road access to the local service hub of Austin (~35km) and Reno International Airport (~310km).

- Groundwater level ~60m below surface providing opportunity for local water source.

Other Projects

The other five projects being acquired as part of the transaction have limited information available and little sampling data has yet been identified in the historical records. Production data provides an indication of the tungsten grades which were mined. The Company continues to review the available data and is making efforts to establish in any additional information is available.

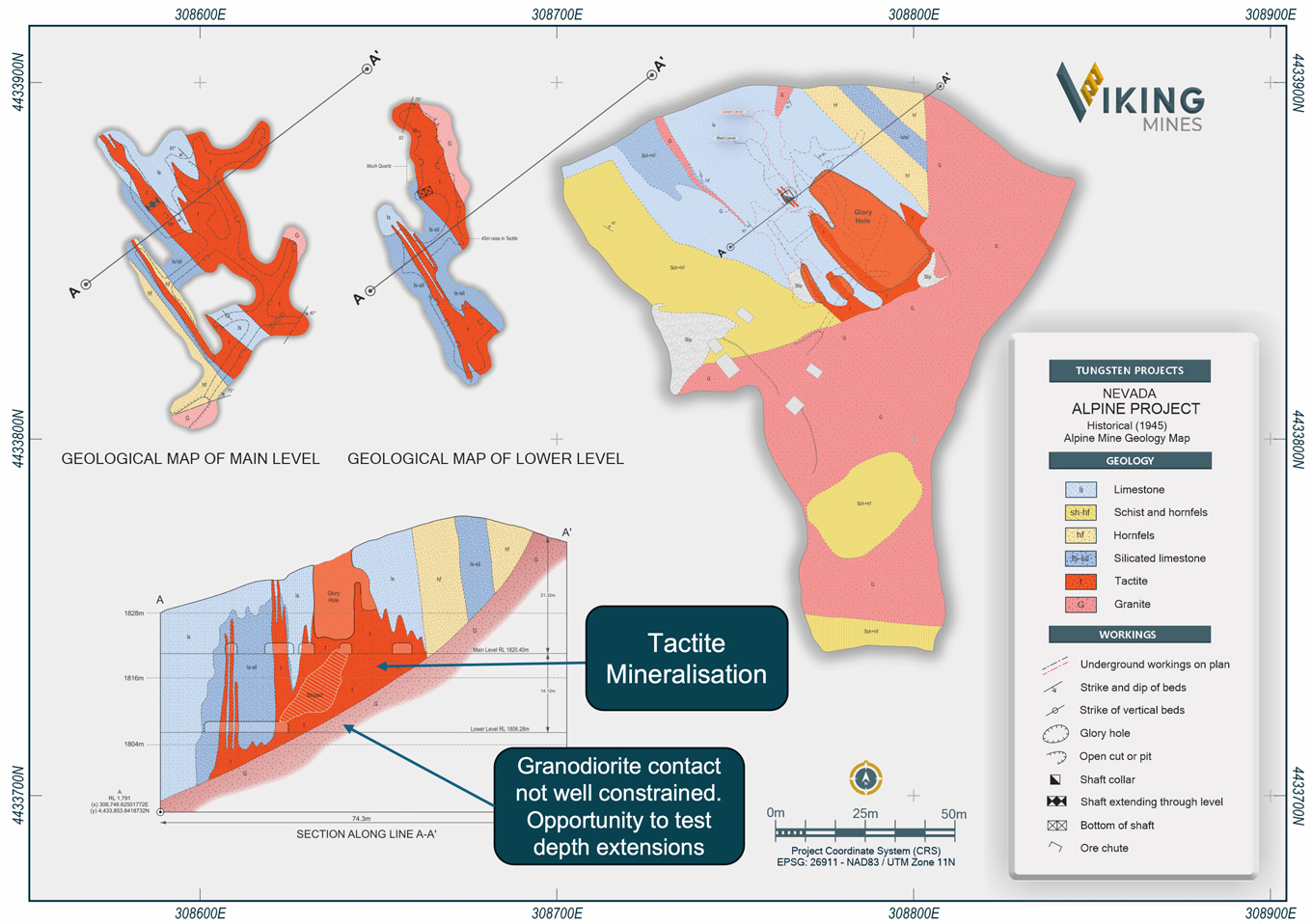

Alpine Project

Encompasses the Alpine Mine and is in the Nightingale District of Pershing County. ~39kt mined at 0.60% WO3 from an open pit and underground with ore remnants noted as remaining in the workings and depth extensions to be tested (Figure 9). No drilling has been reported or identified on the Project and the depth extensions represent a logical target for a first pass drilling programme.

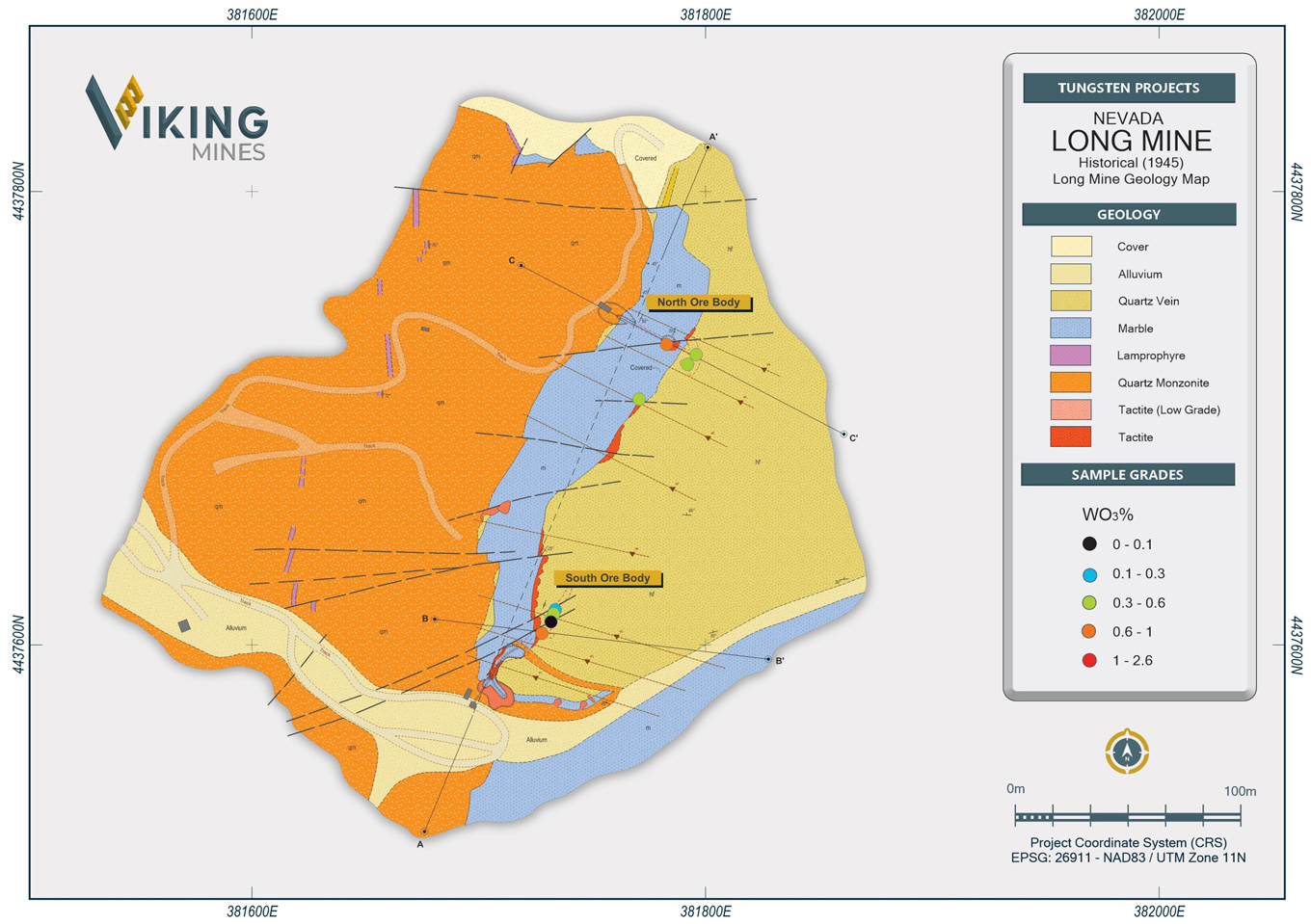

Long Project

Encompasses the Long Mine which produced ~17kt at 0.60% WO3 from 2 separate underground mines operated over 2 levels and occurring on ~200m long contact. The mines extracted scheelite mineralisation from the North and South orebodies (Figure 10). No drilling has been reported or identified on the project and the depth extensions represent a logical target for a first pass drilling programme.

Terrell Project

Encompasses the Terrell Underground Mine with a shallow inclined shaft and underground adits which produced 2.9kt at 0.6% WO3. The Nye Mine is located to the south which is off the BLK claims but demonstrates repeated occurrences of tungsten in the area. Limited data is available and initial activity will involve a more thorough data search, mapping and surface sampling to generate drill targets.

Ragged Project

Comprised of claims to the north of the historical Ragged Top Mine which produced 18kt at 1.00% WO3. The production did not occur on the BLK Group claims, but there remains opportunity for discovery. Initial field activity to involve mapping and rock chip sampling.

Victory Project

Comprised of claims surrounding the historical Victory Mine which produced 93kt at 1.00% WO3. The production did not occur on the BLK Group claims, but there remains opportunity for discovery. Initial field activity to involve mapping and rock chip sampling.

Historical Production

Four of the 6 projects have seen production totalling 123,000t at 0.54% WO3 from the areas covered by the Mineral Claims, with the remaining two projects having production totalling 110,000t at 1.00% WO3 from mines which abut the mineral claims being acquired. The combined production from the claims and adjoining mines totals 233,000t at 0.76% WO3.

The level of historical production from the mineral claims and adjoining mines is significant and at a high-grade and gives the Company confidence that the tenor of mineralisation previously discovered on the projects is of a high quality.